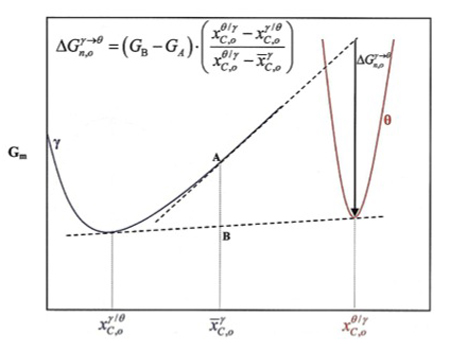

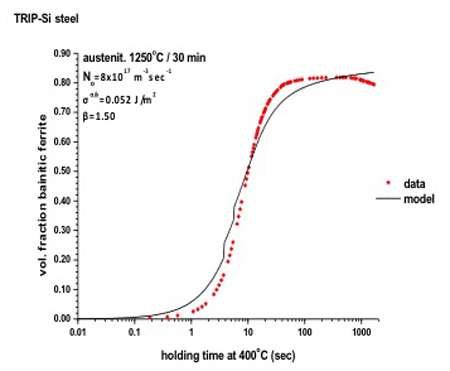

Bainite is playing a major role in the microstructure and mechanical properties in a variety of advanced high-strength steel steel grades. Optimization of the production and exploitation of bainite-involving steel grades and, more importantly, optimization of the design of new alloy compositions and/or processing routes, necessitate the clarification of the effect of chemical composition and heat-treatment conditions on the evolution of the bainitic transformation. This in turn creates a necessity for the development of appropriate models, with the highest possible degree of accuracy and applicability. Of all known models describing the evolution of bainitic transformation the most integrated one, is that proposed by Azuma (2005). It takes into account and quantifies the precipitation of cementite during the bainitic transformation, which allows a more realistic modelling of the bainitic transformation. This makes necessary the evaluation of the driving forces of formation for all participating phases, cementite precipitating from austenite and ferrite as well as ferrite forming from austenite. The evolution of bainite transformation is under paraequilibrium control, so the aforementioned driving forces were calculated under paraequilibrium conditions. This was made possible by modifying the thermodynamic solution database SSOL of the commercial thermodynamic software Thermo-Calc, following the methodology established in an earlier work (Grujicic & Haidemenopoulos 1988). The thermodynamic functions describing a pseudo-binary system of a fictitious element Z with carbon were incorporated into the database. Z accumulates all the thermodynamic functions of the substitutional elements in the initial alloy. Driving forces calculated for the phases of the pseudo-binary system of Z-C in equilibrium are driving forces of the respective phases of the initial alloy in paraequilibrium (Fig.1a). The paraequilibrium driving forces were inserted into the Azuma model and the kinetics of the bainitic transformation were modelled (Fig.1b). Several steel grades were studied and the calculated transformation kinetics for each one was in good agreement with experimental dilatometric results. The influence of parameters such as nucleation-site densities, interfacial energies, transformation temperature, parent austenite grain-size, etc, on the kinetics of the bainitic transformation was studied extensively. This is a more realistic modeling of the bainitic transformation and widens the range of applicability of the model to practically any steel composition. It is anticipated that the development of such reliable modeling tools will enhance the capabilities related to the design and optimization of new alloy compositions.

Contributors: H. Kamoutsi, A. Katsamas, G.N. Haidemenopoulos

References

Azuma, M. (2005). Modelling upper and lower bainite trasformation in steels. ISIJ International, 45(2), pp.221-228.

Grujicic, M. & Haidemenopoulos, G.N. (1988). A treatment of paraequilibrium thermodynamics in AF1410 steel using the thermocalc software and database. Calphad, 12(3), pp.219-224.

|

Fig 1a |

Fig 1b |